Example: 2-3 component items moulded in a single – stages and assembled in the mould

We are constantly seeking innovative and effective solutions for products and processes.

We have been promoting it for years. This technology not only allows us to integrate assembly into the IM process, but above all, it allows us to create innovative products that would otherwise be impossible.

Example: Plastic multi-layer nail polish bottle, technical fitting with through square hole , article with integrated moving part all items not achievable with traditional IM. Achievable with IMA

Produced with bi- and tri-injection technology + IMA techniques

They allow for uniqueness and differentiation on the market and investment savings (they are produced entirely in one go)

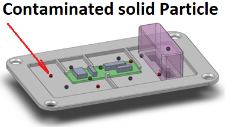

The problem of preventing or removing contaminant solid particle, also concerns plastic items, where cleanliness is considered a quality factor based on the VDA or ISO regulations.

Integrated components and systems for static control , cleaning solution , cleanliness transport and storage System

Customized Cleanliness Injection Moulding Systems